Purpose :

The purpose of this article is to understand the pick denial concept.

Pick denial is an important concept in outbound delivery process where the system could not find any or not enough stock to fulfill the picking request. In such scenario the system performs the short pick and adjust the delivery document (both EWM and ECC) as per the actual pick quantity automatically.

Pick denial use in scenarios where and outbound delivery is processed automatically via waves and the user intervention for quantity adjustment is not required.

Example :

User created the picking request for 10 qty but during picking, user can only find 7 qty to pick. With the Pick denial concept the system pick the available qty and adjust the delivery in EWM and ERP accordingly.

There are two ways to perform the Pick denial:

- Adjust the delivery qty and create the new warehouse request for the remaining qty.

- Adjust the delivery qty and send message to ERP system.

This blog will only cover the second option where the system during pick denial will adjust the EWM delivery qty (with the picked qty) and send the message to ERP system to automatically adjust the delivery qty as per the pick quantity.

Below is the supporting configuration to run the process.

Config:

SCWM-> GI -> Pick denial

- Activate the pick denial at WH level

-

Since pick denial is occur during the creation of warehouse task as the entire quantity could not be made to pick. Here, we can assign the pick denial action against the warehouse process type used for picking where we have two option to select:

- Adjust quantity requested to pick quantity, for this option the system will adjust the outbound delivery qty to the picked qty and for the remaining quantity the system will create another outbound delivery that can be process with the next wave run.

- Adjust quantity in warehouse req. to picked qty and send message, in this scenario the system will adjust the outbound delivery qty to the picked qty and send the message to ERP to adjust the delivery qty to the picked qty in this case another outbound delivery is not created.

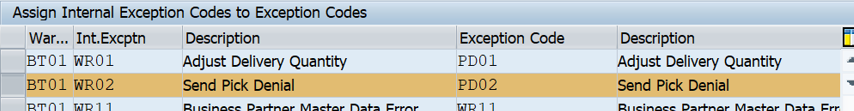

- Assign internal exception code to exception codes.

- Exception codes will be use to run internally during workflow execution's (automatically or manual) during WT creation for picking. Assign internal exception code to exception codes.

- Maintain follow on action and Work flow connection

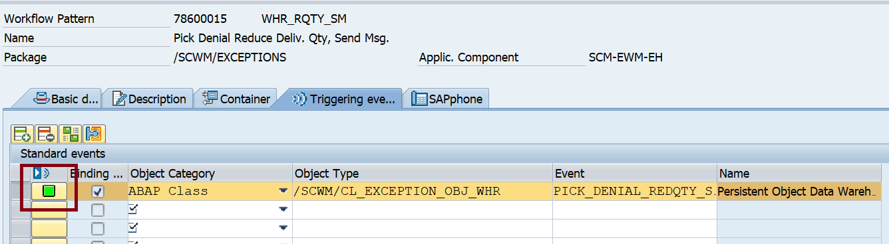

- Define active workflow

- Maintain the workflow setting in system and ensure the workflow setting against the receiver is enabled.

Process flow:

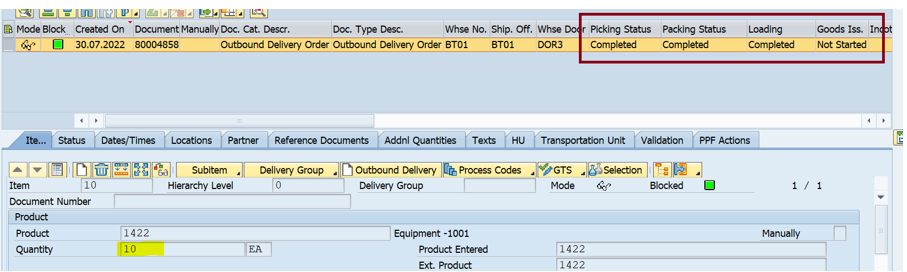

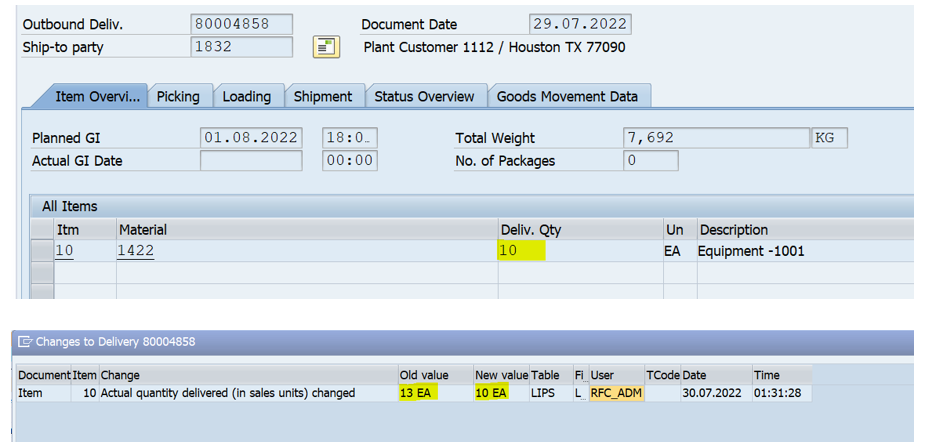

Scenario: The qty in source storage bin is 10 EA, the demanded qty is 13 EA (in Sales order) .

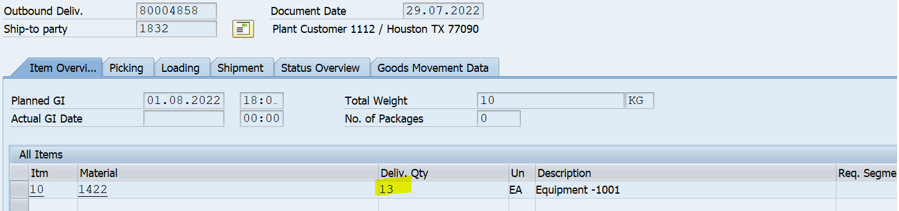

- Outbound delivery (OBD) ECC -13 EA

- Create the picking request in EWM – Due to short of qty the system will through the warning message, this warning message can be bypass by using the config option “Automatic follow-on action in dialog box and background” so that during auto wave picking process the warning should not stop the process (by any chance).

- System picks the correct pick denial option as ‘2’

- Confirm all the warehouse task created against the Outbound delivery in SCM monitor

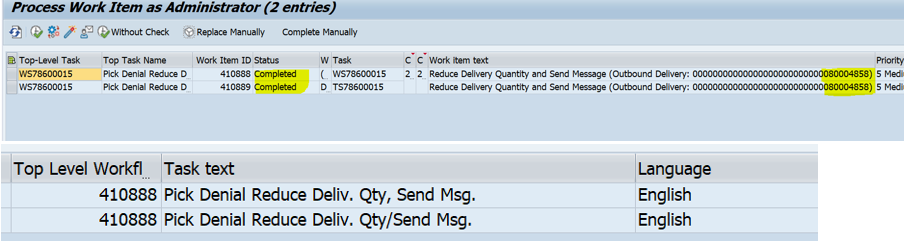

- The system will trigger the workflow where the event “PICK_DENIAL_REDQTY_SENDM” has been called. Execute the work flow and set the status as completed (this step performed automatically in background using PPF)

- Before the workflow execution, the OBD qty is 13 EA

- After workflow execution and status set as completed.

- The EWM Outbound delivery qty will be automatically change to pick qty -i.e., 10 EA

- The ECC Outbound delivery qty will be automatically changed to 10 EA. Due to pick denial option -2 “Adjust the delivery qty and send message to ERP”

Perform Goods Issue in EWM, the GI posting later will be updated in ECC Outbound delivery.

Summary:

- The pick denial process can be used where the user intervention is not allowed/ required and the picking request is created automatically under wave.

- for Pick denial option -1 "Adjust the delivery qty and create the new warehouse request for the remaining qty" the system will only update the EWM delivery qty as pick qty but do not send message to ECC to update the qty instead it creates another WT (from next wave) to pick the remaining qty from other source bin.

Request readers to kindly review and provide your suggestion in comments and also follow me for more such interesting topics.

Thanks to author Nitin Solan