Quality Management plays a key role in the warehouse for different business like pharmaceutical,Bevergaes and FMCG.

The Main purpose of the blog is to explain about EWM-QM Configuration setup and transaction processing with one example

To achieve this we have to go with following steps

1)Create a Material Master with Quality Management and Inspection type

2) Define External Storage Process Steps

3) Define & Assign Storage Process Definition

4) Define Process Oriented Storage Control

5) Define & Determination of Warehouse Process Type

6)Maintain process type indicators and Quality Inspection group at product master level

7)Define work center for Quality Storage type(8020) and bin

8)Define Putaway Strategies

9)Generate Inspection Object Types Version

10)Maintain Inspection Object Types Version

11)Define and Activate Warehouse-Dependent IOTs

12)Define Quality Inspection Group

13)Maintain Follow-Up Actions

14)Maintain Inspection Results

15)Testing

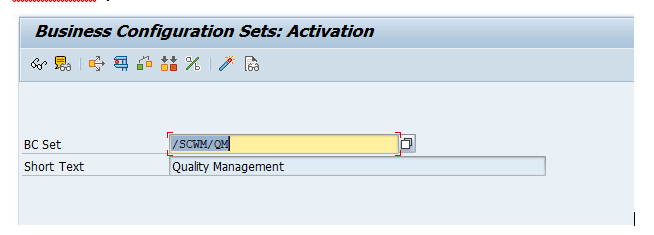

NOTE:NO NEED TO ACTIVATE BC SET IN S4HANA

NOTE:NEED TO ACTIVATE BC SET IN Decentrailsed system

Decentralised system:

1)Create a Material Master with Quality Management and Inspection type

Create a material master -371 with Quality Management view and Inspection Type

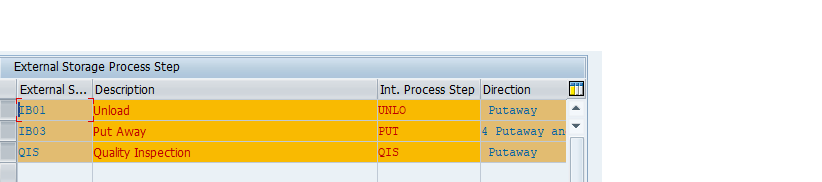

2) Define External Storage Process Steps

Define External Storage Process Steps

IMG Path: SPRO→SCM EWM →Extended Warehouse Management → Cross Process Settings → Warehouse task →Define External storage process step.

3) Define & Assign Storage Process Definition

Define & Assign Storage Process Definition

IMG Path: SPRO→SCM EWM →Extended Warehouse Management→ Cross Process Settings → Warehouse task → Define Storage Process Definition→Assign Storage Process step

4)Define Process Oriented Storage Control

IMG Path: SPRO→SCM EWM → Extended Warehouse Management→Cross Process Settings → Warehouse task → Define process-oriented storage control

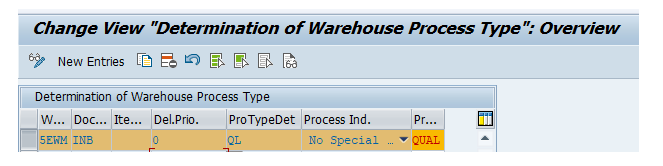

5) Define & Determination of Warehouse Process Type

Define & Determination of Warehouse Process Type

WPT Control indicator

Assign Control Indicator to WPT

6)Maintain process type indicators and Quality Inspection group at product master level

7)Define work center for Quality Storage type(8020) and bin

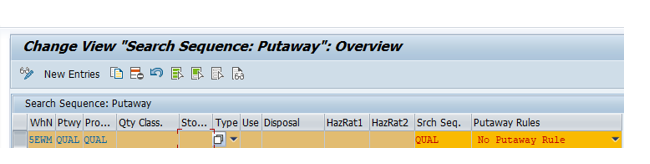

8)Define Putaway Strategies

Quality Management Setup in EWM

9)Generate Inspection Object Types Version

SPRO:IMG→Cross process settings→Quality Management→ Basics and Integration→Generate Inspection Object Types Version

10)Maintain Inspection Object Types Version

SPRO:IMG→Cross process settings→Quality Management→Basics and Integration→ Maintain Inspection Object Types Version

11)Define and Activate Warehouse-Dependent IOTs

SPRO:IMG→Cross process settings→Quality Management→ Basics and Integration→ Define and Activate Warehouse-Dependent IOTs

12)Define Quality Inspection Group

SPRO:IMG→Cross process settings→Quality Management→ Inspection Planning→ Define Quality Inspection Group

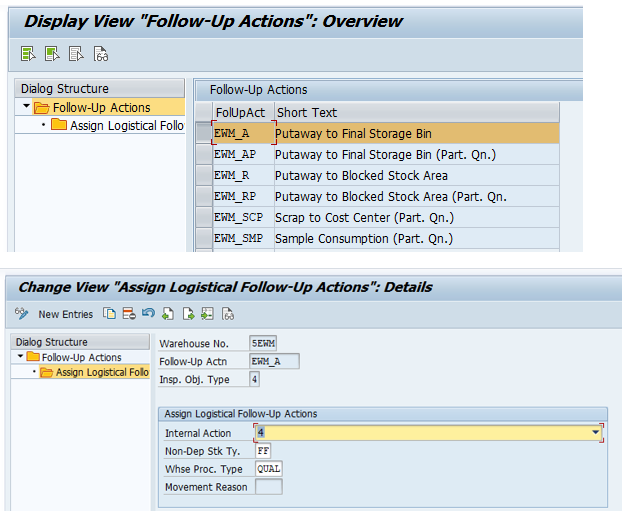

13)Maintain Follow-Up Actions

SPRO:IMG→Cross process settings→Quality Management→ Inspection Results→ Maintain Follow-Up Actions→ Define Follow-Up Actions

14)Maintain Inspection Results

SPRO:IMG→Cross process settings→Quality Managementà Inspection Results→ Maintain Follow-Up Actions→Assign Logistical Follow-Up Actions

SPRO:IMG→Cross process settings→Quality Management→Inspection Results→ Maintain Follow-Up Actions →Assign Default Work Center for Inspections

We need to maintain quality inspection rule in sap easy access it’s a mandatory step

/SCWM/QRSETUP - Maintain Inspection Rule

15)Testing

Create a po and do the delivery

Go to /N/SCWM/PRDI to Process Inbound Delivery

Here we have selected “0” Means Inspection after Goods Receipt .Quality Inspection planned document got created

Check whether the HU has been triggered or not because we are using POSC with Quality

Ibd-follow on action-warehouse task

Create the warehouse task

Confirm the warehouse task .2 Warehouse tasks has been created because HU WT has been ticked in POSC at IB01 step

Confirm the warehouse order

Goto Monitor /n/scwm/mon

Now I will confirm the warehouse task from staging area to quality work centre

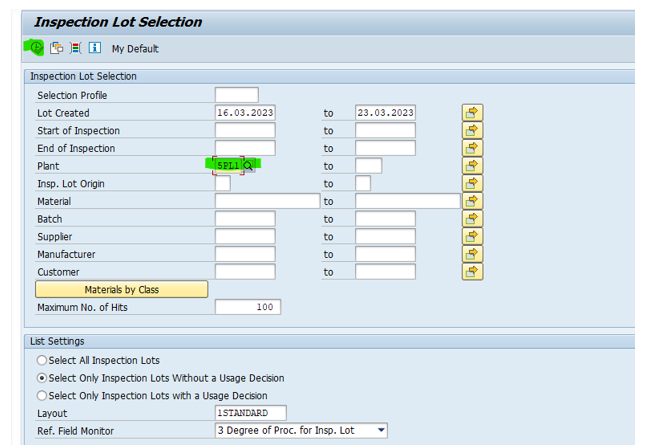

Here we can provide Usage Decision in QA32 please provide your plant details and execute it

Select your inspection lot and click on usage decision

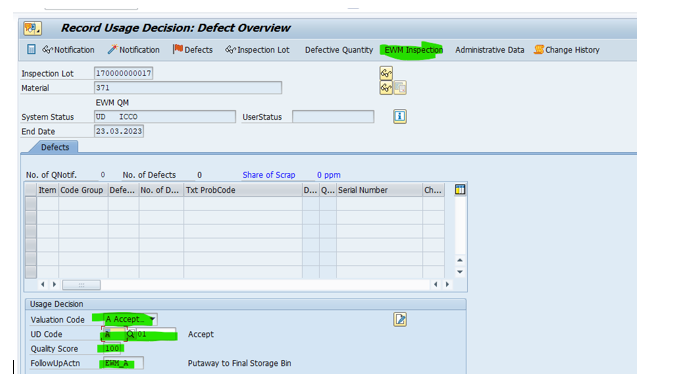

Provide your usage decision code and select EWM Inspection

A new window will be open or (/N/SCWM/QINSP_S4) and provide decision and follow up action

Then close the HU

Once you close the HU then the usage decision for that LOT will be saved

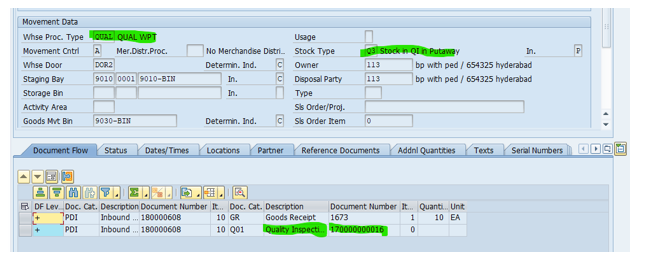

Then one open warehouse task will be available for that the stock type Q3 will be converted to F1 stock type

Now you can confirm the open warehouse task

Please check the stock in Bin

Check in MMBE

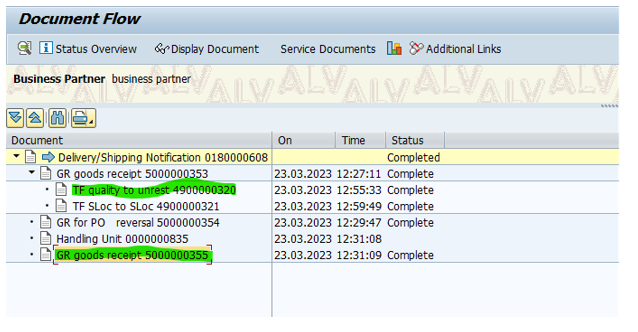

Go to Inbound Delivery and view the Document flow

By above configurations and testing now you got an idea how to config QM with storage processes with respective internal and external steps assigned to it .

Thanks for your patience to read my blog and give your valuable feedback

Thanks to author Saikiran Gummadi